When it comes to lawn mower blades, the idea of “reverse threaded” mainly applies to the nuts used to secure the blade. This design prevents the blade from loosening during operation. It’s crucial to refer to your mower’s manual or manufacturer guidelines to determine the specific thread direction for your blade’s nuts. Following these recommendations ensures safe and effective maintenance of your lawn mower.

Are Lawn Mower Blades Reverse Thread? Solutions

Most homeowners and lawn care enthusiasts often wonder whether or not the blades of a lawn mower are reverse threaded. One should therefore understand it for safekeeping and replacing the blades when necessary.

In this context, reverse threading is the opposite direction in which nuts used to secure the blades to mower decks tighten as compared to normal threading.

This unique feature primarily enhances safety and stability during mowing processes. Consequently, the process of loosening or tightening of mower blades is reversed by using reverse threading thereby making them less likely to become loose as you continuously cut through grass resulting in a decreased possibility of accidents occurring or damage being inflicted on the lawnmower itself.

Therefore, the knowledge that lawn mower blades are reversely threaded is vital so that they can be properly kept up with efficient and safe lawn maintenance can be observed.

Lawn Mover Reverse Thread

Understanding Are Lawn Mover Reverse Thread

This article answers the question: Are lawn mover blades reverse threaded? To understand it, let us first define reverse threading. In standard threading, turning a bolt or nut clockwise makes it tighter, whereas turning counterclockwise loosens it.

On the other hand, in reverse threading, moving counterclockwise tightens the bolt or nut while turning clockwise loosens it. Despite its apparent contradiction to instinct, this reversal serves certain importance well.

Are Lawn Mower Blades Reverse Threaded?

Yes, some of them are. Manufacturers might decide on using reverse threads for a number of reasons such as improvement in safety and stability during operation.

By way of implementing thread reversals, mower blades can be kept from becoming loose as they are used thus limiting dangers that may arise like accidents and damage to the machine itself.

Are Lawn Mower Blade Nuts Reverse Threaded?

In many cases, these nuts do have reverse threads just like those of the mower blades so that they perfectly fit onto each other during mowing on lawns that are frequented by people and animals.

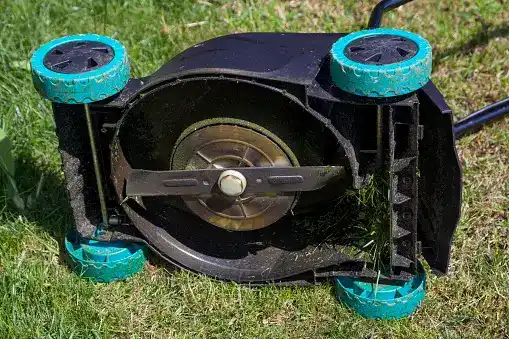

How Do Lawn Mower Blades Work?

To cut grass effectively and keep your turf healthy overall requires utilizing cutter sections beneath the mower frame, The spinning motion makes these blades whirl rapidly through grass stalks with great accuracy.

The design quality as well as sharpness of these parts determines how well they do their job thus defining your garden’s look and health.

Craftsman Mower Blades Reverse Threaded?

There may or may not be reverse threading on Craftsman mower blades depending on individual models and designs.

It is important therefore to refer to the manufacturer’s manual or visually check whether Craftsman mower blades are correctly threaded.

Are Toro Mower Blades Reverse Threaded?

As some of the Craftsman blades are, so are Toro mower blades sometimes.

When purchasing or using this product, it is important to look at the product specifications available from Toro and engage authorized dealers to know the type of threads that their blade uses.

Also, More Read: How to Easily Free a Stuck Pull Cord on Your Lawnmower

Are Cub Cadet Mower Blades Reverse Threaded

Cub Cadet mower blades could be reverse threaded on specific models like those made by other manufacturers.

To determine if a certain Cub Cadet mower blade is reverse threaded it may be necessary to check the product guide provided or ask one of the company’s representatives.

How to Find Out if a Lawn Mower Blade Is Reverse Threaded

Determining whether a lawn mower blade has reverse thread is relatively simple. Before trying to remove the blade, inspect how the retaining nut moves in relation to its threading direction.

Therefore, if you cannot turn it anti-clockwise but you can do so clockwise then it means that there is reverse threading in place. Moreover, manufacturers usually provide labels or user manuals that indicate prescribed thread types.

John Deere Lawn Mower Blades

John Deere is among the top names in lawn care machinery and their mowing blades are no exception. Made with precision and durability in mind, John Deere lawn mower blades are designed to deliver optimal cutting performance.

Available in various sizes and configurations to suit different mower models, John Deere blades ensure a clean and uniform cut for a pristine lawn.

Craftsman is one more well-known brand that is identified with quality and dependability. Their lawn mower blades are designed to satisfy the needs of domestic and commercial users alike.

No matter whether you need to mow overgrown thick grass or finely cut turf, Craftsman blades are made for that. These mowers have good materials and cutting edges that are accurate; therefore, they always give excellent results.

Troy Bilt Lawn Mower Blades

They make different lawn mower blades for various kinds of lawnmowing which are available at Troy Bilt. The company is known for mulching, standard high-lift blades as well as those meant for bagging your clippings.

With these designs in place, it has been made easier for homeowners to achieve the desired results in their lawns. To sustain regular cutting, Troy Bilt makes its own unbreakable blades which serve customers’ needs accordingly as many people choose them among other groups.

Cub Cadet Lawn Mower Blades

Cub Cadet prides itself on being a provider of performance-based lawn care systems including its own variety of mower blades.

Cub Cadet has developed high-efficiency and durable blade materials that ensure they remain sharp throughout their lifetime periods hence avoiding frequent replacements because they wear off quickly due to use in grass fields.

Cub Cadet gives homeowners precision cuts using the best possible equipment available when trimming small backyards or extensive landscapes thus making it a beloved choice for most people who have an opportunity to buy it Must Compile.

Step 1: Power Disconnection

Before removing the blades, make sure the mower is fully disconnected from power. This entails unplugging electric mowers and disconnecting spark plug wires in gas-powered ones. Safety is always a priority when dealing with lawn mower knives.

Step 2: Secure Blades

Wearing proper safety equipment such as gloves, raise the deck of the mower so you can reach its blades. Once exposed; use a wood piece or blade remover to hold the blade in place though. This will keep it from spinning as you loosen its retaining nut.

Step 3: Recall Blade Position

Make sure that you remember how the blade is oriented before pulling it out. Installing them incorrectly can affect cutting performance and safety since some blades are designed off-centeredly.

Step 4: Lose The Nut!

Loosen the bolt keeping your blade securely in place by using an appropriate size wrench or socket. Also, remember that certain lawn mower blades may have reverse threading hence take care when turning the nut around.

Apply constant force to get rid of corrosion without damaging threads on the nut.

Step 5: Join the New Blade

Unfasten the nut, and then cautiously remove it together with the blade from the mower deck. Take this period also to appraise any damages or wear out on the blade.

Replace it with a new one if necessary or sharpen it.

Take care as you fix in place a replacement blade and tighten well the retaining nut that holds it.

Conclusion

In conclusion, whether lawn mower blades are reverse threaded is an important aspect of lawn maintenance to consider. A proper understanding of threading direction for mower blades and their securing nuts is essential for the safe and effective running of mowers.

Reverse threading in mower blades helps to enhance safety by reducing the chances of them becoming loose as one mows hence lessening the possibilities of such accidents or damage.

By becoming conversant with this feature, homeowners will ensure proper blade installation and maintenance thus making their lawns neat without much hustle during mowing.

Above all, recognizing why reverse threading occurs on lawn-mower blades so that they can be more vigilant about how they take care of their lawns shows how much attention to detail counts when looking at matters concerning modern gardening practices.

FAQs:

1. What does it mean if lawn mower blades are reverse threaded?

Reverse threading in lawn mower blades means that the nuts securing the blades onto the mower deck tighten in the opposite direction compared to standard threading.

2. Why are some lawn mower blades reverse threaded?

Lawn mower blades are reverse threaded to enhance safety and stability during mowing operations. This design feature reduces the likelihood of blades loosening due to the rotational force exerted while cutting grass.

3. How can I tell if my lawn mower blades are reverse threaded?

To determine if your lawn mower blades are reverse threaded, observe the direction in which the retaining nuts tighten and loosen. If turning counterclockwise tightens the nut and clockwise loosens it, the blades are likely reverse-threaded.

4. Can I use regular tools to remove reverse threaded nuts on mower blades?

While regular tools may suffice, using tools specifically designed for reverse threading can ensure easier and safer removal of nuts. It’s essential to exercise caution and follow manufacturer guidelines when working with mower blades.

5. Are there any benefits to having reverse threaded lawn mower blades?

Yes, reverse-threaded lawn mower blades offer increased safety and stability during mowing by reducing the risk of blade loosening. This can help prevent accidents and damage to the mower, ensuring a smooth and efficient lawn care experience.

Leave a Reply