INTRODUCTION

Electric PTO (Power Take) clutches are of paramount importance to landscaping professionals and avid gardeners in the smooth operation of their heavy-duty equipment.

The electric PTO clutch, when used in mowers and other garden machines, helps in power transfer from the engine to the cutting blades or auxiliary applications efficiently.

However, troubleshooting must be done promptly and correctly once a problem occurs so that it does not affect operational efficiency. This comprehensive guide is aimed at helping professionals, as well as enthusiasts, diagnose and solve common electric PTO clutch issues.

Knowing How Electric PTO Clutches Work

Riding lawnmowers, including zero-turn models, have electric PTO clutches that do this job, while others are found in various gardening attachments.

Role: An electric current passing through the clutch when the operator flips a switch energizes it, which then establishes a magnetic field. Consequently, that causes the engagement of clutch plates with cutting blades, thus transferring power to them.

Engagement Mechanism:

Typically, electric PTO clutches use electromagnetic principles for their engagement mechanisms. In such cases, engaging involves passing current through a coil, resulting in the formation of a magnetic field that pulls mating plates together, enabling power transfer.

Disengagement:

Whenever there is a removal of current from the coil, its magnetic field ceases, causing disconnection between plates and thus breaking down power transmission.

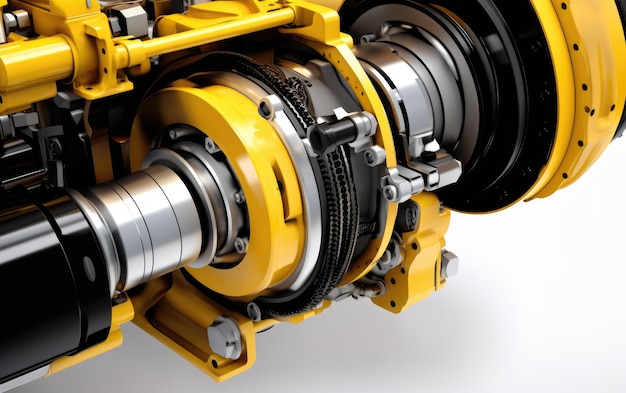

Components :

There are quite several components involved in an electrical power take-off (PTO) clutch. They include an electromagnetic coil, rotor, field shell, stator, drive sleeve, and driven disc, all secured by springs and fasteners to make up the assembly.

Common Malfunctions and Signs

Signals manifesting themselves when an electrical PTO clutch has malfunctioned can come out in several ways, calling for attention:

Blades Won’t Engage: Sometimes blades won’t engage after flipping on your switch, usually due to an electrical fault or a mechanical problem inside the clutch itself.

Blades Won’t Disengage: Sometimes the opposite occurs where blades don’t stop moving after being disengaged; this may be due to electromagnetic issues or mechanical problems such as rust or debris.

Overheating: Inadequate adjustment, a misaligned system, and heavy usage are some of the factors that cause overheating in clutches.

Noisy Operation: Unusual sounds during blade engagement or operation can arise from many things, such as worn bearings or misaligned components.

Symptoms of a Bad PTO Clutch

Being aware of signs showing an impaired PTO clutch can prevent further damage to landscaping equipment. Below is a list of symptoms that, if noticed early enough, can help in solving them:

Slipping Clutch: This happens when the clutch fails to engage fully, leading to slower motion of the blades than usual and fluctuations in their speed, which are often caused by wear and tear on the faces of the clutch plates or a lack of tension in its spring assembly.

Failure to Engage or Disengage: Instead of common malfunctions where there might be some level of engagement happening, this shows a complete failure to engage and disengage, hence pointing out serious electrical and mechanical faults within the clutch systems.

Burning Smell: A peculiar burning smell while operating means that your clutch has become excessively hot. Such cases result from misalignment of the clutch and breakdowns occurring at its electromagnetic coil.

Unusual Vibrations

Experiencing an imbalance in the clutch assembly, often caused by damaged or worn parts, is a possible indication of unusual vibrations resulting from engaging the clutch.

Electrical Issues

An intermittent clutch operation or non-responsive engagement switch, such as the one it did not respond to, can be a sign of electrical problems, among them faulty wiring and an engagement switch that malfunctions occasionally.

Reducing downtime and repair costs can depend on recognizing these symptoms early and ensuring your equipment remains in top operating condition.

Troubleshooting Steps

steps to diagnose the problem are as follows if you have any of the above issues:

Check Power Source:

Make sure that there is enough power in the mower’s battery and that electricity flows through the entire electrical system into the PTO clutch.

Inspect Wiring:

Examine all corroded, destroyed, or detached wires that may cause electrical faults.

Voltage Test:

If there is sufficient voltage when engaged, check with a multimeter whether the PTO clutch is getting the correct voltage reading.

Continuity Test:

Do this when disengaged to see if there’s a complete circuit for carrying electricity after completing this continuity test.

Inspect clutch components:

The clutch should be disassembled to see whether wear signs, corrosion, or damage, especially in engagement mechanisms like the coil and armature plate, exist.

Engagement Test:

Components must move smoothly and entirely while being engaged for them to be observed during their engagement with the clutch.

Disengagement Test:

Parts must detach freely without any residual mechanical or magnetic forces holding them together upon disengaging a lever.

Temperature Check:

Running a machine with an engaged clutch checks the temperature of the running one; overheating could indicate trouble.

Refer to the manufacturer’s documentation:

In addition, always use manuals that will provide troubleshooting procedures for your electric PTO clutches.

Professional Assistance:

Calling upon professionals’ help would also help in case you do not know how skilled you are or if whatever you have is not enough to solve the problem.

Husqvarna Electric PTO Clutch Troubleshooting

Troubleshooting the electric PTO clutch on a Husqvarna riding mower necessitates a step-by-step procedure of checking and solving minor problems that may hinder it from operating as expected. Here are steps custom-made to address potential problems for Husqvarna models:

Check Clutch Engagement:

Engagement Issue: If your Husqvarna mower fails to engage, test your battery voltage by ensuring it supplies full power. Insufficient power can lead to a non-engaging clutch.

Inspect the safety switches:

Most Husqvarna mowers have safety switches installed in them, which prevent the mower from moving when certain conditions are not met. Ensure these safety switches, like the seat switch, brake switch, and deck switch, are operating correctly, and there’s another reason why the PTO clutch won’t engage.

Clutch Air Gap Adjustment:

There is a specific air gap setting for the PTO clutches on Husqvarna mowers that is critical for proper clutch engagement. Consult your mower’s manual for exact specifications and adjust the air gap using a feeler gauge if necessary.

Wiring and connector inspection:

Check all wiring and connectors between that handlebar panel (where you push down to engage the blade) with the plunger on it and the connector at the bottom of the machine, where the wires go towards the clutch connection. Look for any signs of wear, damage, or loose connections that could interrupt the flow of current to clutches.

Electrical Testing:

You need to test the voltage at the clutch connector to make sure it gets 12 volts when the PTO switch is on. If there is no engagement but the voltage is correct, then most likely the issue lies with the clutch coil.

Mechanical Inspection:

Inspect that clutch for mechanical damage such as worn-out bearings, a damaged pulley, or a stuck clutch mechanism when you take it off your mower. Failure of mechanical components can prevent them from disengaging or engaging properly.

Replacement:

In case all checks and tests have been done and nothing works, then replacement may be required. To enhance performance, choose the right replacement part that is specific to your Husqvarna model.

Final Remarks: Correct troubleshooting of your Husqvarna’s electric PTO clutch can save you from unnecessary replacements and ensure your mower operates efficiently. To complete any maintenance or repair work, refer to your Husqvarna model manual for specific guidance and safety instructions.

Practical Tips for Maintenance

Preventive maintenance plays a huge role in ensuring that one does not experience problems with their electric PTO clutch. Here are some practices that serve the best

Regular Inspection:

Frequently check the state of the clutch as well as its adjacent parts to see if they are wearing out.

Cleanliness:

Make sure that dirt doesn’t accumulate around, on, or within this system; otherwise, debris would get into and between these two plates, causing slipping or loss of efficiency on this device.

Lubrication:

Some clutches will only function correctly if they receive periodic lubrication; therefore, use manufacturer-recommended lubricant sparingly, as stated by them.

Tension Adjustment:

It has to be done in the right way so it won’t prevent proper friction drive-belt tensioning or disconnection mechanism functioning; moreover, the manual should give more information about how often to do this operation.

Electrical Connections:

If the wiring leading towards it becomes loose over time, wire insulation may wear out in some places, thus causing the malfunction of the clutch.

Temperature Monitoring:

To identify overheating problems Watch for any temperature changes in the clutch while it is running.

Proper Usage:

When using blades, avoid engaging or disengaging them at high speeds, as these actions lead to wear and tear on your clutch’s parts if you do so often enough.

Storage:

After completing its functionality, it should be stored in a well-cleaned place that lacks humidity to keep corrosion away from this tool.

Regular Maintenance Schedule:

Develop a schedule for this device and follow it. For example, you can plan two maintenance checks per year; one should be done before the summer season and the other after it.

Documentation:

The record of performed maintenance will help you avoid mistakes in the future.

John Deere Electric PTO Troubleshooting

When to call an Experienced

There is always a point during any DIY repair where one must know when to call professionals; here’s when they are needed most.

Complex Electrical Issues:

A professional auto electrician or mower technician would be required if the problem is related to the electrical system of the mower beyond the clutch itself.

Specialized Tools Required:

Better equipped than ordinary mechanics, who can do some diagnoses without requiring special equipment, particular diagnostic tasks demand hiring professionals because they need special tools.

Warranty Concerns:

Bear in mind that by letting people not authorized by the manufacturer repair your machine, your warranty may be violated.

Safety Concerns:

Sometimes repair work can pose a danger, especially when connected to operations with electricity or heavy units.

Lack of Progress:

If diligent troubleshooting has not led to identifying the issue, a professional’s experience and knowledge might be instrumental.

Manufacturer Recommendations:

Sometimes it may be that the amount of time required to solve a problem is inconsistent with the retained value of hiring an expert.

Manufacturer Recommendations:

“Service professionals,” as per the manufacturer, when multiple attempts have not led to a resolution.

Conclusion

The efficient operation of landscaping and gardening equipment depends on the health of your electric PTO clutch. This can save landscapers and gardeners money and time, among any other possible inconveniences.

Besides these points, it’s important for landscapers and gardeners to know everything about electric PTO clutch systems and always prioritize safety when using them. Maintenance tips are available in our guide, along with ways to get professional help if need be.

Share your own experiences and tips for electric PTO clutch troubleshooting in the comments below. Let’s have a healthy discussion about maintaining garden equipment for a blossoming garden and thriving business.

FAQs

Q: How do I perform a voltage test on the electric PTO clutch?

A: Set the tool multimeter to voltage mode, then the ground wire is connected. The other lead will be attached to the power source wire before engaging the PTO for readings. Be cautious not to touch or connect the meter incorrectly, leading to shock or electrical malfunction.

Q: What should I look for when inspecting the wiring connected to the electric PTO clutch?

These include exposed wires, myriads of loose connections, cuts, chafing, or corrosion. Examples include cuts on the wires, corroded connectors, or insulation damage—just a few common examples of such electrical problems giving rise to issues like this one.

Q: What could be causing the electric PTO clutch not to engage properly?

A faulty switch, wiring problems, a damaged or loose belt, a coil that has stopped working, or a bearing that has seized up are some examples of the ordinary culprits behind this problem.

Q: How can I troubleshoot overheating issues with the electric PTO clutch?

This may involve checking for any leaks or blockages in the surrounding components that could be putting extra pressure on them. Tensions should be adjusted correctly, and worn or damaged components are common within the clutch assembly.

Q: When is it necessary to repair or replace the electric PTO clutch?

However, with troubleshooting revealing a more serious problem like extensive wear and tear or an electrical component that can never be fixed again, replacement may be required.

Nevertheless, the majority of clutches have replaceable parts, so they can be serviced well. Replacements and repairs should always follow the manufacturer’s instructions.

Leave a Reply